What is a Lithium Battery?

Lithium batteries are used to store a large amount of electric energy. The energy is stored as chemical potential difference between electrodes.

The batteries are rechargeable – lithium ions ‘rock’ back and forth between the cathode and anode to generate electricity. This is what makes them so good for mobile technologies – they have a high charge density.

Electrochemical Reactions

The electrolyte in a lithium battery acts as a physical barrier that keeps the cathode and anode from touching each other. It allows lithium ions to move between them, but only under stringent conditions.

The main degradation pathway of lithium batteries is the formation of Solid Electrolyte Interface (SEI) film, which progressively depletes the cyclable Li+ inventory and leads to high ohmic impedance and reduced Ah charge. The plating of metallic Li on the anodes is also a significant issue that can lead to sulphation, irreversible capacity loss and cell fires.

To understand these issues, ex situ NMR is used to monitor the bulk changes in the solid parts of the battery during different states-of-charge and cycling. The results of this study show that the amount of penetrated Li+ ions in the silicon at the end of the first cycle (Supplementary Fig. 1) is comparable to the prediction of a two-way diffusion trapping model. Moreover, the large discrepancy between calculated and experimental individual silicon and graphite states-of-charge at high SOCs indicates that the SEI is not fully saturated.

Electrolyte

In lithium batteries, electrolyte reactions are key to achieving good performance and long lifetimes. They affect the specific surface area of the negative electrode, the plating of metals in the electrolyte solution, and the internal resistance of the battery during charging and discharging.

In button-cell or coin lithium batteries (used in hearing aids, watches, electronic votives and other battery-operated devices), the electrolyte is a liquid or gel that contains charged ions (cations). When an electric potential is applied, cations are drawn to an electrode with a surplus of electrons while anions move away from an electrode with a deficit of electrons. The movement of these ions generates a current.

Researchers are trying to improve the chemical and electrical properties of electrolytes in order to achieve better cell chemistry and higher energy density. They are also exploring strategies to overcome the limits of current cell chemistries, such as multielectron reactions and expanding the operation voltage window. To achieve these goals, a battery-specific solid-electrolyte interface must be designed. This is a challenging task since there are many factors that influence the SEI formation.

Cathode

When the battery is discharging, lithium battery lithium ions leave the anode and travel through the electrolyte to the cathode. This releases electrons that are tied to the anode and flow through an external wire, generating electricity. During recharging, the process is reversed.

The negative electrode in a lithium battery is made from graphite, and the positive is usually some kind of metal oxide. But the repeated insertion of lithium ions into standard graphite eventually breaks it apart and reduces its performance. Researchers are working on options like silicon-based alloys that could improve performance.

The cathode is the most critical element of a lithium lithium battery battery, and its performance has the biggest impact on a battery’s specs. For example, it takes six carbon (graphite) atoms to bind one lithium ion. But if you can pack more atoms into the anode, it can hold 10 times as much electric charge.

Anode

The anode and cathode determine the capacity and voltage of lithium batteries. The separator acts as a physical barrier between the anode and cathode while carefully keeping ions separate from electrons and allowing only ions to move between the two electrodes during charging. This is why the separator must satisfy very stringent physical and electrochemical conditions.

The anode reacts with the electrolyte to store lithium ions. Graphite is the dominant anode material because it allows one lithium ion to be stored for every six carbon atoms in the material. Graphite has good cycle stability and performance, but it isn’t as high in energy density as other materials like silicon.

The anode reactions are complex and influenced by many factors including its morphology, texture, crystallinity and other characteristics. The ability of the anode to reversibly absorb/emit lithium ions also plays a big role in battery’s capacity and voltage. Silicon is being looked at as an alternative to graphite for the anode because it can contain more lithium ions than graphite. However, the insertion/emission of Li + from silicon can cause a cracking effect in the anode that leads to catastrophic failure.

Safety

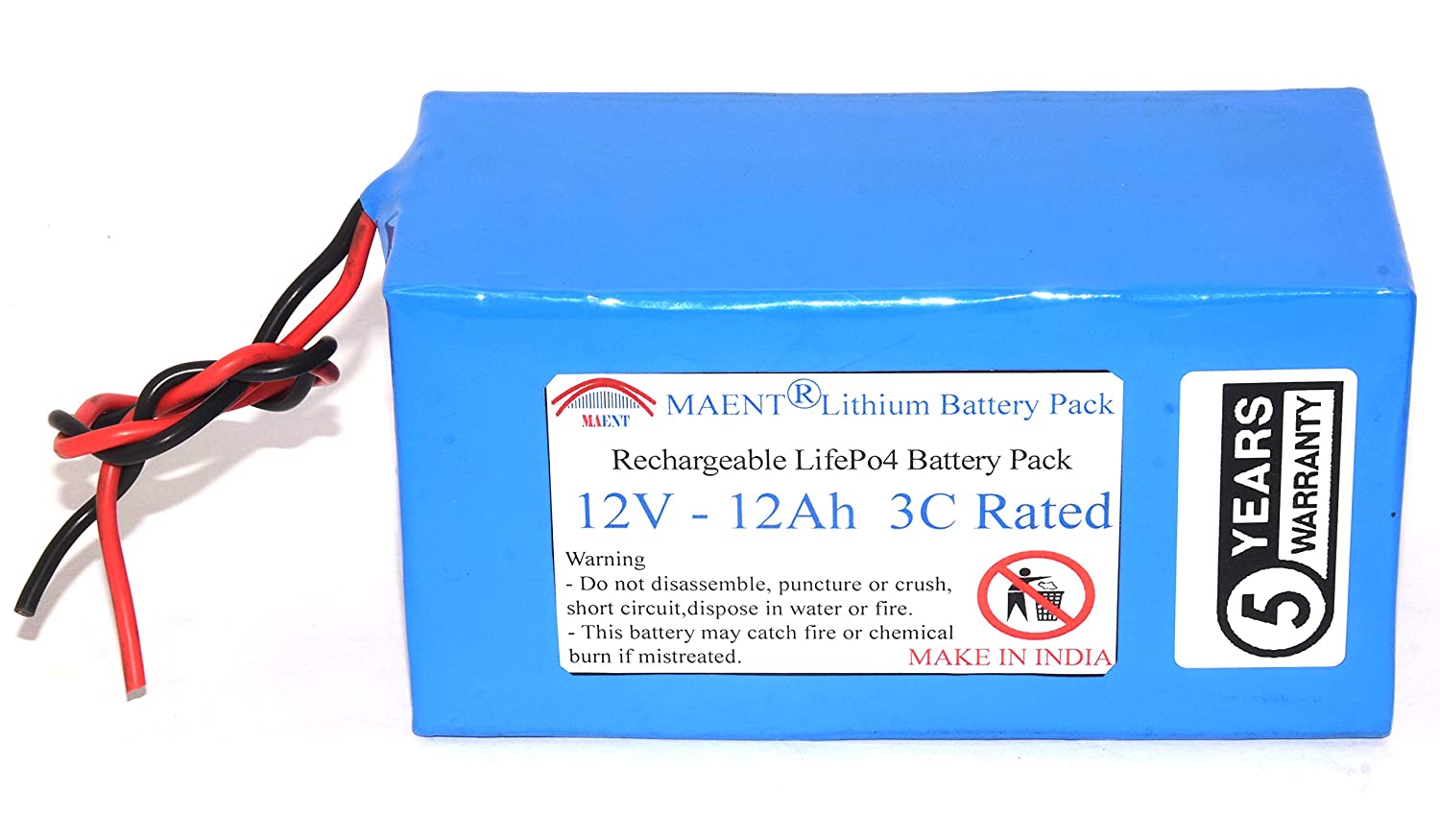

Lithium batteries supply power to a wide variety of devices including smart phones, laptops, e-scooters and e-bikes, e-cigarettes, smoke alarms, toys and cars. When they are not used correctly or damaged, they can overheat, catch fire or explode.

The safety of lithium batteries relies on a complex set of physical and electrochemical features. These include a separator that keeps the cathode and anode apart but allows only lithium ions to pass and a battery’s electrolyte which must meet stringent physical conditions and chemical properties.

Additional safety measures include PTC, CID and pressure vents which stop cells, modules or packs from overheating and exploding by increasing resistance at high temperatures and cutting the positive terminal off from the anode respectively. All these can provide significant protection from hazards but they do not prevent damage to the battery itself.

Finch consultants can help you manage risks associated with lithium battery systems and implement control measures. These can include storage procedures, information and PPE. They can also provide training for tradespeople to increase knowledge and awareness of these potential dangers.